From Prototype to Process Heat Plant to Electric Power Plant

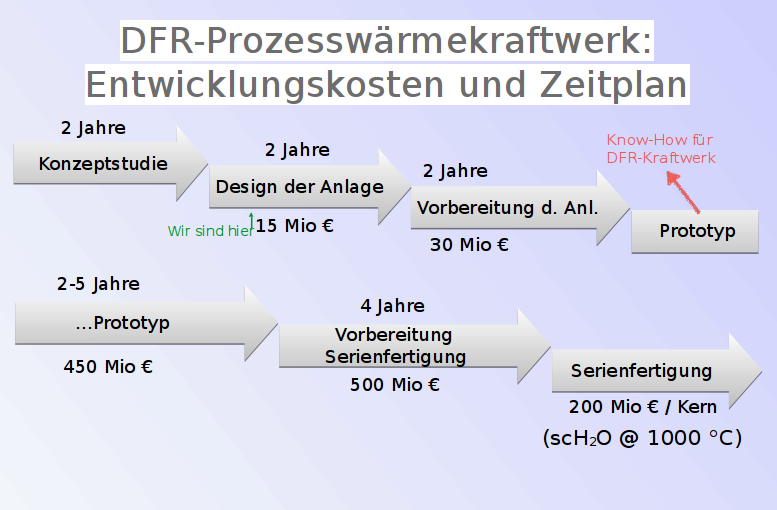

In order to develop the first DFR power plant, it is advisable to start out with a pure process heat plant (300 MWth, no turbogenerator). The following diagram shows how within eight years for a sum of one billion Euro first a prototype could developed and from this a mass production model:

DFRs of the 300-MWth-class could be produced like aircraft in factories on an assembly line. Mass production prices clock in at 200 million Euro per unit.

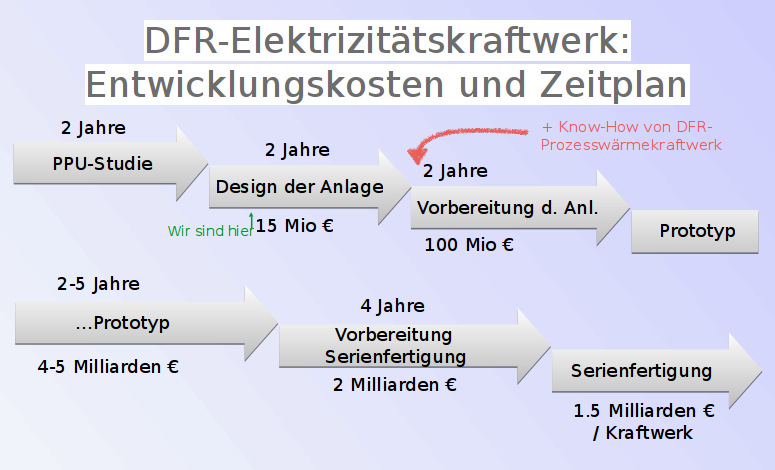

The know-how gathered in the course of development of the process heat plant will come in use when the first electricity plant is constructed. Here, too, development will lead from a prototype to mass production. Eight billion Euro need to be invested, with mass production prices at 1.5 billion Euro per unit.

To build the first DFR which is not composed of computer files and paper, but of silicon carbide, molybdenum, steel and concrete, one to several billion Euro need to be invested — a seemingly large sum, but tame in comparison with yearly renewable subsidies in Germany (25 billion). Some money could be redirected from solar and wind to technologies that actually do have the potential to compete with oil, gas and coal — or a foreign investor steps in.