How does the DFR compare with other Reactor Types?

What is the basis for the Dual Fluid Reactor’s exceptional properties? A look at the data of other Generation-4-concepts is useful here.

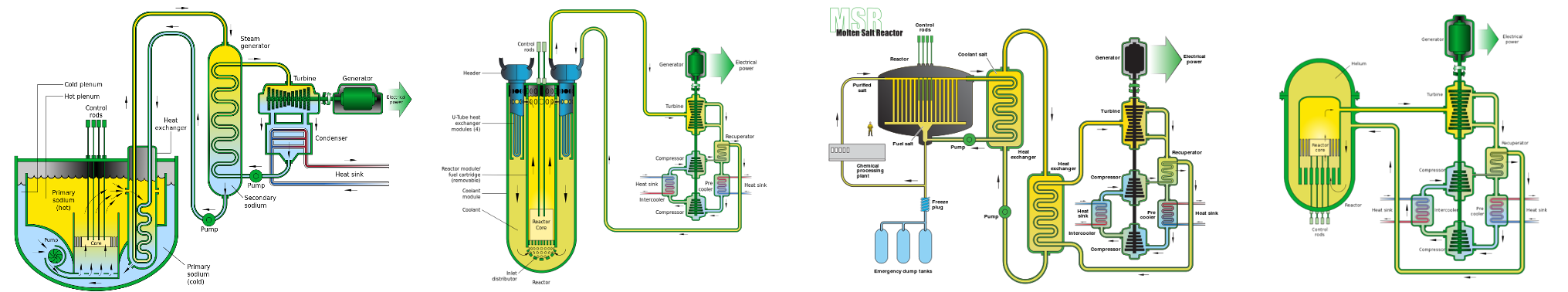

The table below (source: Thomas Dolan, “Molten Salt Reactors and Thorium Energy”, chapter 25: “Dual Fluid Reactor”) lists some key properties of both types of DFR (salt and metal fuel) and compares them to those of the SFR (sodium-cooled fast reactor), MSR (single-loop molten salt reactor), LFR (lead-cooled fast reactor), GFR (gas-cooled fast reactor) and last not least the LWR (light-water reactor).

Comparison of Selected Parameters

Doubling time in the Pu-U-Cycle (timespan for the reactor to produce a startup mass of fissile material for another reactor — depends on the frequency of reprocessing; the greater the frequency, the shorter the doubling time)

While LWRs aren’t able to create more fissile fuel than it itself consumes, the other reactors listed are breeding capable, though the GFR only with difficulty. LFR, SFR and MSR have doubling times between 10 and 20 years; the DFR/s 13 years, the DFR/m reaches the record value of 8 years. This makes it especially suitable for rapid nuclear buildup, especially as it can be started with a load of low enriched uranium.

Required storing time of waste

The LWR leaves behind wastes contaminated with transuranics, which need to be stored for some hundreds of thousands of years. Fast neutron reactors coupled with suitable reprocessing technology (for the DFR: the PPU) create a pure fission product waste stream, which after 300 years falls below the radiotoxicity of natural uranium.

Power density of the core

This parameter is of great importance for the economy of power plants, as it is a measure for the amount of material (and human work hours and money) that needs to be utilized per MW of installed capacity. In this respect the two DFR variants win the crown, they clock in at 150 (DFR/s) or even 250 (DFR/m) MW/m³. While the LFR still achiebed 140 MW/m³, the other types are markedly below 100, some kinds of GFR even below 10 MW/m³. While this is often mentioned as safety bonus, size and costs are massively increased.

Mechanical control elements?

As all movable parts of a system are necessarily subject to wear and material fatigue, the absence of such is a great plus to safety. Only MSR and DFR can do without control rods, with the MSR needing some in case the fuel is reprocessed offline.

Process heat applications

This calls for high operating temperatures: GFR, LFR and the liquid fueled reactors are process heat capable, MSR and LFR only with massively increased efforts, though (they operate at 1100 K). The DFR clocks in at 1300 or even 1350 K (DFR/m) — the king of process heat machines! These high temperatures also enable very efficient electricity generation (60%).