From Nuclear Fission to Electricity

Just imagine: On a bright September morning in 2030, you’re driving your hydrazine-powered car along the US West Coast. Some miles south of San Clemente, you glance leisurely out at the bright turquoise expanse of the Pacific Ocean — a small industrial compound at the beach catches your attention: “Right”, you think, “good old SONGS. It’s great that they decided to shut down the old light-water reactors.” San Onofre Nuclear Power Station doesn’t look much like your grandfather’s nuclear plant. The mighty concrete domes are gone: In their place, there are just a cooling tower and unobstrusive artificial hills covered with grass — little indication that some tens of meters below ground, machines release fantastic amounts of energy. The turbine halls are smaller than those of an equivalent light-water based plant, and next to the waterfront, a few buildings drink seawater through trunk-like metal tubes: Californian draughts are a footnote in history books since DFR-powered desalination has rolled around.

Nuclear reactors generate heat. For it to perform work which is useful for humanity, it needs to be converted into exergy (directional energy, work): Electricity or chemical energy. This is what a power plant does.

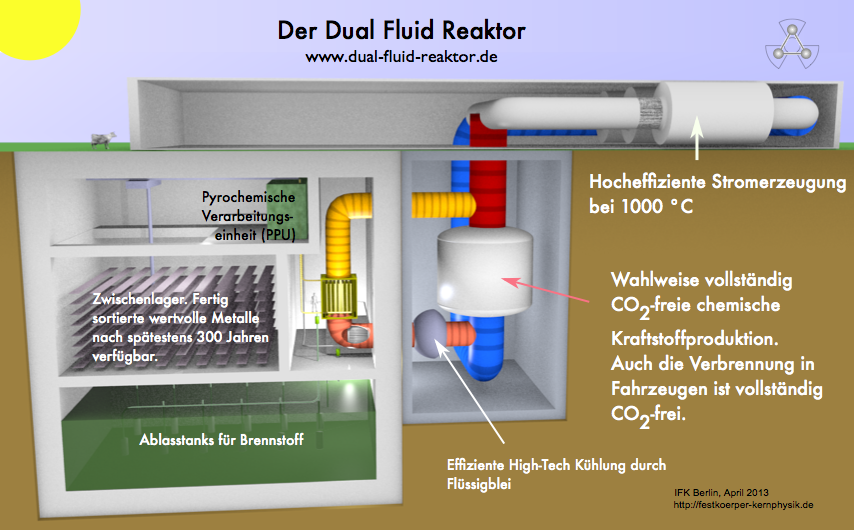

The following illustration shows what a DFR power plant might look like:

The DFR’s compact size makes it possible to set up all nuclear components under ground, in hardened concrete bunkers. With the exception of complicated burrowing bombs or high explosive bunker busters, no weapon can penetrate the “hot zone”. (Terrorists or criminals are unable to obtain such advanced weapon systems, since their production necessitates a highly developed military industry, and the nations which have such — USA, Russia, China — store them in hardened facilities.)

The white concrete domes of which people usually think when they hear “nuclear power” will thus be a thing of the past in the DFR Age! Their purpose is to contain steam which in the case of reactor vessel rupture will shoot out of the primary circuit. The DFR operates at atmospheric pressure and doesn’t create any steam itself — being a fast reactor, it contains neither water nor any other substances with small atomic weight. The dome becomes superfluous.

As the DFR’s high operating temperature enables efficient energy conversion, most cooling towers can be phased out, too — even smaller rivers or lakes are suitable heat sinks. The only parts of a DFR plant visible at surface level will be the turbine building and the transformer station.

In nations with a built-out power grid, power plants of the gigawatt class are the best solution. Smaller grids (e.g. on islands) may also incorporate Mini-DFRs putting out a few hundreds of megawatts.

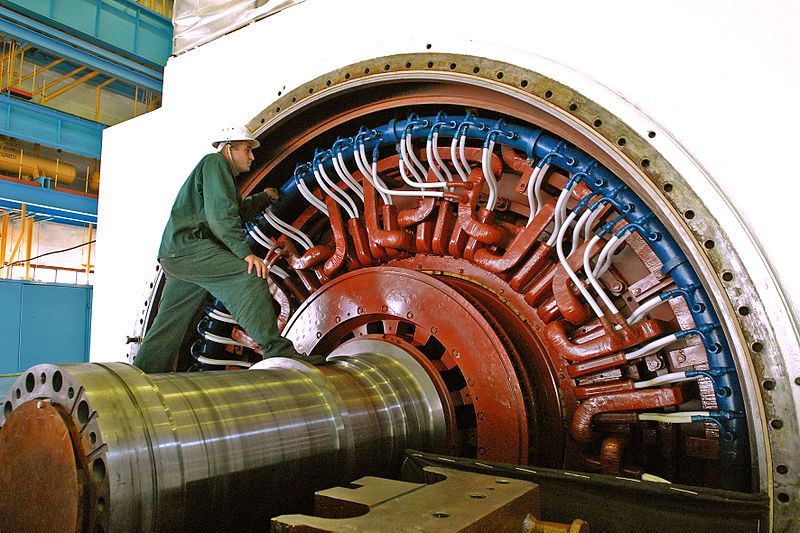

The Turbo Generator

(Source), powered by steam; DFR plants will use supercritical water or carbon dioxide, instead.

Since lead hardly suffers any neutron activation, the primary circuit of the DFR can be extended into the conventional part of the plant. Here, its energy is transferred to the turbine loop in a recuperator. The turbine is driven by a medium of markedly lower heat capacity: supercritical water (scH2O) — a special state of matter in between liquid and gas —, likely the most economical solution. Turbines for supercritical media have more in common with gas turbines than with steam turbines, as there is no phase transition within the loop and a turbocompressor is needed. Modern coal-fired plants already operate at 700 °C using scH2O turbines, temperatures of up to 1000 °C shouldn’t be problematic, either, as the blades are made from very sobust materials which are able to withstand dust, sulfuric acid and steam at 1400 °C. Supercritical carbon dioxide could be another possibility.

Process Heat Applications

If the reactor is to operate partially or fully as a process heat plant, the conventional part must be modified. The lead loop either heats a chemical reactor directly, or it transfers its heat to an additional liquid loop. For mixed use — electricity and process heat —, the latter is extracted first, with the turbine loop operating at a somewhat lower temperature.

The Pyrochemical Processing Unit (PPU)

The Pyrochemical Processing Unit is based on the same principle.

“Isn’t PUREX extremely expensive and environmentally unfriendly?”, many ask, when they hear the word “reprocessing”. This is true. Plutonium-Uranium Recovery by Extraction, developed in the course of World War II, is an aqueous chemical process generating lots of toxic waste while being extremely complicated and imprecise. Therefore, a completely different technology was developed for the DFR — or rather: borrowed from other branches of industry and adapted to nuclear use.

Seawater desalination, titanium production, petrochemistry and liquor industry: Separation of substance mixtures using temperature gradients is nothing new. With the PPU, it enters the nuclear industry big style for the first time.

The fuel liquid is evaporated and the steam flows through a column, in which a temperature gradient has been established. Each element or element group rains out at a specific temperature. This enables homogeneous separation of all fission products — depending on the mode of operation, certain substances can be extracted in pure form. Good news for doctors and patients: The radiotracer technetium 99m, which is created from molybdenum 99, can now be produced at every electric power plant in large amounts, with no need for expensive research reactors.

If a DFR/m (metallic fuel) is used, the fuel liquid must first be converted to a chlorine salt before it enters the PPU, as molten metals have too high boiling points. Afterwards, the chlorine is removed again.

The PPU does not only extract the fission products: it is also used to feed in fresh nuclear fuel. If irradiated fuel from light-water reactors is to be used, a reduction step must be added in front of the PPU, removing the oxygene from the uranium oxide.

Find out more about the PPU on our nuclear waste page.

Fission Product Storage

The extremely low material flow through a nuclear reactor (about 1.2 t / gigawatt-year) makes in possible to securely store alle wastes accumulating over its entire lifetime on the plant’s premises. As the PPU extracts all substances in element-pure form, different types of storage depending on half-life are possible.

Long-lived fission products are sealed and transported by a robotic arm into a storage unit below the PPU room, in which they will stay until their radioactivity has declined sufficiently to allow removal and further industrial use. 90% of all fission products can be handled after 100 years, including many noble metals and rare earths. (Thanks to the PPU, they come pre-sorted.) The remaining 10% should remain in storage for about 300 years. Extremely long-lived fission products are transmuted into shorter-lived isotopes in the DFR through neutron irradiation.

The fission product storage is cooled via the chimney effect through natural air circulation.

The shortest-lived fission products can add to energy production, utilizing their decay heat. They are stored in liquid phase in tubes embedded in the lead loop. Their container is connected to tubes which, normally blocked by melt plugs, lead to the storage tanks. These are surrounded by steel ingots (which look somewhat similar to LEGO blocks), buffering decay heat and dissipating it slowly to the surrounding ground.

Other Applications

The fission products’ radiation may trigger chemical reactions: Radiotomic chemistry may find its place in a DFR plant, as well as production facilities for medical technetium generators.